Late afternoon. Public holiday. 60 Jolimont Street, East Melbourne.

The phone rang. Cricket Australia’s headquarters—home to the World Cup trophy, the T20 Cup, and Don Bradman’s priceless cap and bat—was flooding.

A burst hot water system had released thousands of litres across the first floor. Water was spreading through the executive office, computer room, kitchen, foyer, and large open-plan workspace.

350m² of carpet tiles completely saturated.

Australia’s cricket heritage at risk.

And this was actually the second time Cricket Australia had called us.

Here’s the day-by-day account of how we dried out one of Australia’s most important sporting headquarters—and what commercial property managers can learn from a 15-day restoration that protected priceless memorabilia and kept business operating throughout.

Why Cricket Australia Called Us (Twice)

Before I walk you through the 2020 restoration, you need to understand why Cricket Australia chose us for the second time.

The First Occasion (Years Earlier)

The disaster: A $2.50 washer let go on a public holiday. Thousands of litres of water flooded through three floors of their headquarters.

What was at stake: The same priceless memorabilia. The World Cup trophy. The T20 Cup. Don Bradman’s cap and bat. Decades of Australian cricket heritage.

The result: Within 7 days, completely dry. Zero damage to any memorabilia. Business operating with minimal disruption (only 3 days of staff sent home).

The Second Occasion (2020)

The disaster: Another failure. Different public holiday. This time, two floors affected instead of three.

Cricket Australia’s response: They didn’t call around for quotes. They didn’t wait for their insurance company to assign a restoration contractor. They didn’t hesitate.

They called us immediately.

Because when you’re protecting Australia’s cricket heritage, you don’t take chances with companies you don’t know. You call the team that’s already proven they can do the job.

This case study is from that second occasion. April-May 2020. 350m² affected. 15 days of intensive restoration. Here’s exactly how we did it.

Day 1 (Wednesday, 29 April 2020): The Public Holiday Emergency

The Call Comes In

Late afternoon. Anzac Day public holiday observed. Most of Melbourne is relaxing. We’re on standby.

The call: Burst hot water system at Cricket Australia headquarters. Water throughout first floor. Extent unknown. Could we come immediately?

Within 60 minutes, we were on-site at 60 Jolimont Street, East Melbourne.

The Scene

The first floor was flooded:

- Executive office (soaked)

- Computer/server room (water everywhere—critical!)

- Kitchen facilities (flooded)

- Reception foyer (water pooled)

- Large open-plan workspace (carpet saturated)

Total affected area: 350m²+ of carpet tiles

And somewhere in this building: The World Cup trophy. The T20 Cup. Don Bradman’s cap and bat. Irreplaceable pieces of Australian sporting history.

Initial Assessment

Water source: Burst hot water system (Category 1 clean water—good news)

Flooring: Carpet tiles throughout (easier to work with than broadloom)

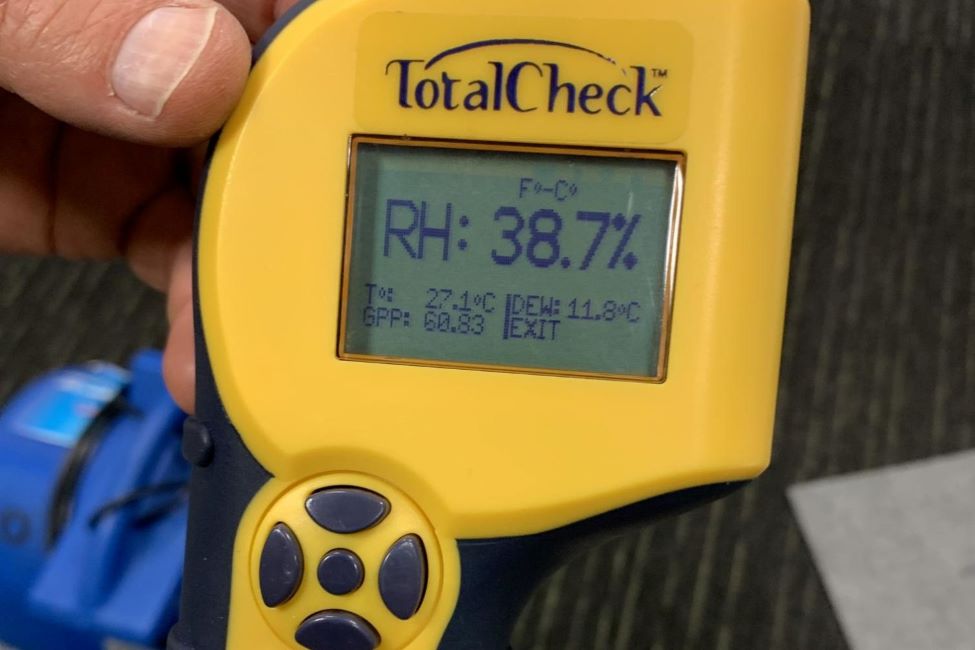

Humidity reading: 70% (dangerously high—mould risk in 24-48 hours)

Moisture levels: Severe saturation in all affected areas

Priority concern: Computer/server room. Water and electronics don’t mix. Business continuity depends on this equipment.

Secondary concern: Priceless memorabilia. Where was it located? Was it at risk? (Assessment revealed items were protected, but nearby areas needed careful monitoring)

The Public Holiday Challenge

This wasn’t a Tuesday morning. This was a public holiday.

What that means:

- Limited access to additional equipment if needed

- Skeleton staff at Cricket Australia

- Suppliers closed

- Difficult to coordinate if problems arise

What we had going for us:

- We own our equipment (don’t need to rent)

- Our team was available

- We’d done this building before (knew the layout)

- We had Cricket Australia’s trust

Immediate Response (Day 1)

Actions taken:

- Emergency water extraction across entire 350m² area

- Truck-mounted extraction system deployed

- Removed as much water as possible from carpet tiles

- Focus on computer room first (business critical)

- Initial equipment deployment:

- 7 commercial dehumidifiers

- 13 industrial air movers

- 1 air scrubber (air quality protection)

- Strategic placement for optimal airflow

- Documentation begun:

- Photos of all affected areas

- Initial moisture readings recorded

- Humidity levels logged

- Thermal imaging scans completed

- Cricket Australia briefed:

- Explained the 15-day timeline estimate

- Discussed business continuity options

- Outlined daily monitoring plan

- Provided emergency contacts

End of Day 1 status:

- Water extracted

- Equipment running

- Building secured

- Initial humidity: 70%

The team left late that night knowing: This was a big job. And Cricket Australia was trusting us with some of Australia’s most priceless sporting treasures.

Day 2 (Thursday, 30 April): Scaling the Response

Morning Assessment

Humidity check: 65% (5% drop—good progress overnight)

Moisture levels: Still high but showing initial drying

Equipment performance: All units running optimally

The Critical Decision

After reviewing overnight progress, we made a call: We needed more equipment.

The 350m² area, the amount of water, the moisture readings—our initial deployment wasn’t enough for the timeline Cricket Australia needed.

Most companies under-deploy equipment to save costs. They drag out the job over 3-4 weeks with minimal equipment.

We over-deploy to finish faster. Why?

- Faster drying = less business disruption

- Faster drying = lower mould risk

- Faster drying = better outcomes

- Cricket Australia needed their headquarters operational

Equipment Scaled Up

New deployment:

- 10 dehumidifiers (up from 7)

- 28 air movers (doubled from 13!)

- 1 air scrubber (maintained)

This wasn’t a small increase. This was a massive scale-up.

Why most companies can’t do this: They don’t own enough equipment. They’d need to hire additional units. By the time they organize rentals, it’s days later.

We could deploy immediately because we own 30+ air movers and 12+ dehumidifiers. No waiting. No coordination. Just move equipment from our warehouse to the site.

Cost of this equipment investment: $200,000+ in professional-grade drying equipment

Value to Cricket Australia: Shaved days off timeline. Reduced business disruption. Lowered risk.

Why This Matters

According to IICRC standards, proper equipment ratio for structural drying is approximately 1 air mover per 10-15m² of affected area.

For 350m²:

- Minimum requirement: 23-35 air movers

- Day 1 deployment: 13 air movers (under-equipped)

- Day 2 deployment: 28 air movers (proper ratio achieved)

This is the difference between professional restoration and prolonged problems.

End of Day 2 status:

- Humidity: 65%

- Equipment: Scaled to full deployment

- Cricket Australia: Confident we had this under control

Day 3 (Friday, 1 May): Accelerated Drying

Major Progress

Humidity reading: 45% (dropped 20% in 24 hours!)

This was significant progress. From 65% to 45% in one day showed the equipment scaling was working.

Equipment Repositioning

Important principle: Air movers don’t just sit in one spot for days.

As areas dry, airflow patterns change. Water migrates to cooler spots. Corners dry slower than centers.

We repositioned all equipment based on:

- Moisture meter readings

- Thermal imaging scans

- Airflow pattern analysis

- Problem area identification

This daily repositioning is what separates professional restoration from amateur.

Senior Technicians Assessment

Two of our senior technicians attended specifically to assess structural drying needs.

Why: In large commercial properties, you need experienced eyes looking at:

- Wall cavity moisture (hidden behind surfaces)

- Subfloor saturation (under carpet tiles)

- Ceiling cavity concerns (water migration upward)

- HVAC system contamination risk

- Structural element damage

Their assessment: Structural drying progressing well. No hidden moisture concerns detected (thermal imaging confirmed). Continue current approach.

End of Day 3 status:

- Humidity: 45%

- Drying rate: Accelerating

- No structural surprises found

Day 4 (Saturday, 2 May): Peak Equipment Deployment

Continued Progress

Humidity reading: 40% (entering safe zone)

Below 60% humidity: Mould risk drops significantly

Below 50%: Comfortable territory

At 40%: Excellent progress

Additional Equipment Added

Despite good progress, we added more equipment:

Peak deployment reached:

- 12 dehumidifiers (increased from 10)

- 30 air movers (increased from 28)

- Air scrubbers maintained

Why add more when already progressing well?

Because “good progress” isn’t the same as “fastest possible.” With Cricket Australia needing their headquarters operational, every day saved mattered.

The weekend work advantage: With most staff working from home (COVID-19 context), weekend drying was actually optimal. Equipment could run 24/7 without disrupting anyone.

Equipment Repositioning (Again)

Daily repositioning continued. Focus areas:

- Corners (always dry slowest)

- Under workstations (restricted airflow)

- Junction between rooms (moisture accumulates)

- Computer room (highest priority)

End of Day 4 status:

- Humidity: 40%

- Equipment: Peak deployment

- Timeline: On track

Days 5-6: The Authorization Wait

Day 5 (Sunday, 3 May): Steady Progress

Daily checks:

- Moisture levels monitored

- Equipment repositioned

- Humidity stable at safe levels

- Carpet tiles drying well

But: Subfloor beneath carpet tiles still showing moisture.

The issue: Carpet tiles were drying nicely. But water had penetrated underneath. The subfloor (concrete slab) had absorbed moisture.

The solution: Need to remove carpet tiles to dry subfloor directly.

The problem: Can’t remove carpet tiles without authorization.

Why Authorization Matters in Commercial Restoration

In residential work, homeowner can give immediate go-ahead.

In commercial work—especially with insurance claims—you need:

- Building manager approval

- Insurance assessor authorization

- Coordination with business operations

- Documentation that removal was necessary

We couldn’t proceed without authorization, even though we knew it was necessary.

Day 6 (Monday, 4 May): Authorization Received

Morning: Authorization received to remove carpet tiles

Action taken:

- Carpet tiles systematically removed from all affected areas

- Stacked and stored properly

- Subfloor exposed for direct drying

- Equipment repositioned to target subfloor

Why this was critical:

Carpet dries in 2-4 days typically.

Concrete subfloor? 7-14 days.

If we’d kept carpet tiles in place, moisture in the concrete would have wicked back up into the tiles. We’d dry them, they’d get damp again. Endless cycle.

Only solution: Remove tiles, dry subfloor completely, then assess tiles for reinstallation or replacement.

End of Day 6 status:

- Tiles removed

- Subfloor exposed and drying

- Equipment optimized for subfloor drying

Day 7 (Tuesday, 5 May): Disposal and Continued Monitoring

Carpet Tile Removal

Decision made: Tiles would not be reinstalled. Disposal approved.

Action taken:

- All carpet tiles removed from premises

- Proper disposal arranged

- Documentation provided for insurance claim

Focus shift: 100% attention on drying subfloor completely.

Daily Monitoring Continued

- Moisture meters on subfloor every 2-3 meters

- Equipment repositioned based on readings

- Thermal imaging to verify no hidden moisture

- Documentation updated

This is day 7 of 15. Almost halfway through.

Most companies would be done by now (they’d have dried the surface, called it good, and left).

We’re continuing because we know the subfloor needs more time. Because we won’t leave until moisture readings say it’s safe.

End of Day 7 status:

- Tiles disposed

- Subfloor drying progressing

- Patience required (this takes time)

Day 8 (Wednesday, 6 May): Insurance Assessor Meeting

On-Site Meeting

Insurance assessor visited to:

- Review progress

- Verify documentation

- Discuss remaining timeline

- Approve continued drying

What we presented:

- Daily moisture logs (8 days of data)

- Humidity progression (70% → 40%)

- Thermal imaging scans showing hidden moisture elimination

- Equipment deployment records

- Photos documenting entire process

Assessor’s response: “This is the most thorough documentation I’ve seen. Continue as planned.”

This is why insurance assessors specifically request us for commercial jobs. Our documentation is scientific, complete, and indisputable.

Equipment Repositioning

Based on latest moisture readings, equipment repositioned again to target stubborn areas.

End of Day 8 status:

- Assessor satisfied with progress

- Documentation approved

- Continued drying authorized

Days 9-10: Progressive Equipment Removal

Day 9 (Thursday, 7 May): First Equipment Reduction

Moisture levels: Significantly improved

Action taken:

- 9 dehumidifiers removed (3 remaining)

- 21 air movers repositioned to concentrate on stubborn areas (9 remaining)

Why remove equipment gradually?

If you remove everything at once and moisture rebounds, you’re starting over.

Better approach: Progressive removal.

- Remove equipment from fully dry areas

- Concentrate remaining equipment on problem spots

- Monitor for moisture rebound

- Only proceed when confident

Day 10 (Friday, 8 May): Further Reduction

Continued progress in all areas.

Equipment scaled down again:

- 5 more dehumidifiers removed

- 12 more air movers removed

- Remaining equipment concentrated on final stubborn areas

Equipment left running through the weekend for final drying phase.

End of Day 10 status:

- Most areas verified dry

- Minimal equipment on remaining problem areas

- Final phase beginning

Days 11-13: Final Drying Phase

Days 11-12 (Weekend): Continuous Operation

Equipment ran continuously over weekend. No daily visits (not necessary at this stage).

Day 13 (Monday, 11 May): Drying Equipment Removal

Major milestone: All areas verified dry.

Final moisture readings:

- Every area below 15% moisture content (safe level)

- Humidity stable

- No moisture rebound detected

- Thermal imaging confirms no hidden moisture

Action taken:

- All dehumidifiers removed

- All air movers removed

- Drying phase complete

Air Quality Phase Begins

New equipment installed:

- 2 additional air scrubbers (total of 3 now)

- HEPA filtration

- 3-day air quality improvement phase

Why air scrubbers after drying?

Even though water is gone, the air quality needs improvement:

- Remove any residual particles

- Eliminate any slight odors

- Ensure absolutely fresh environment

- Final step before business returns fully to normal

According to Safe Work Australia, air quality is critical in commercial properties, especially in shared workspaces and food preparation areas (Cricket Australia’s kitchen was affected).

End of Day 13 status:

- Drying complete

- Air quality improvement phase begun

- 2 days until final clearance

Days 14-15: Final Verification and Clearance

Day 14 (Tuesday, 12 May): Continued Air Scrubbing

Air scrubbers ran continuously for optimal air quality.

Day 15 (Wednesday, 13 May): Final Verification

Complete restoration check:

- All moisture levels verified safe (final readings logged)

- Air quality tested

- All equipment removed

- Final walk-through with Cricket Australia

Areas verified:

- Executive office: ✓ Dry and ready

- Computer room: ✓ Verified safe for equipment

- Kitchen: ✓ Hygiene standards met

- Foyer: ✓ Ready for visitors

- Open-plan workspace: ✓ Fully restored

Cricket Australia cleared to fully reoccupy.

The Final Numbers

Timeline: 15 days from emergency call to final clearance

Area affected: 350m²

Peak equipment deployment:

- 12 dehumidifiers

- 30 air movers

- 3 air scrubbers

Daily monitoring visits: 13 days straight

Moisture readings taken: 200+

Photos documented: 150+

Humidity progression: 70% → 40% → stable

Mould growth: Zero

Damage to memorabilia: Zero

Business disruption: Minimal (COVID work-from-home helped)

Cricket Australia’s response: They called us again for future needs

What Made This Restoration Successful

Looking back at this job, here’s what made it work:

1. Immediate Response on Public Holiday

Challenge: Public holiday, limited resources available

Our advantage: We own our equipment and have team on call 24/7

Result: On-site within 60 minutes, extraction begun immediately

2. Equipment Capacity

Challenge: 350m² requires significant equipment

Other companies: Would need to hire additional equipment, causing delays

Our advantage: Own 30+ air movers and 12+ dehumidifiers

Result: Could scale from 13 to 30 air movers within 24 hours

3. Willingness to Over-Deploy

Conservative approach: Minimal equipment, longer timeline, lower cost

Our approach: Maximum equipment, faster timeline, better outcome

Result: 15 days instead of potential 4-6 weeks with minimal equipment

4. Daily Monitoring and Repositioning

Amateur approach: Set equipment and leave it

Professional approach: Daily moisture readings, daily equipment repositioning, continuous optimization

Result: Accelerated drying, no missed moisture

5. Scientific Documentation

Why it mattered: Insurance assessor approval, Cricket Australia confidence, professional accountability

What we provided: Daily logs, thermal imaging, moisture readings, photo documentation

Result: No disputes, no questions, complete trust

6. Patience with Subfloor Drying

Temptation: Call it done when carpet dry

Reality: Subfloor takes longer

Our approach: Didn’t pack up until subfloor verified dry

Result: No moisture rebound, no callbacks, no mould

7. Business Continuity Focus

Commercial difference: Residential = inconvenience. Commercial = revenue loss.

Our approach: Understood Cricket Australia needed minimal disruption

Result: Coordinated around their operations, optimized for fastest completion

Lessons for Commercial Property Managers

If you manage commercial properties in Melbourne, here’s what the Cricket Australia case study should teach you:

Lesson 1: Know Who to Call BEFORE Disaster

Cricket Australia didn’t wait for insurance to assign a contractor. They called us immediately because they already knew we could handle it.

Action for you: Establish relationship with restoration company now. Don’t wait for emergency.

Lesson 2: Equipment Capacity Matters

Most restoration companies can’t scale from 13 to 30 air movers overnight. They don’t own the equipment.

Questions to ask potential vendors:

- How many air movers do you own?

- How many dehumidifiers?

- Can you scale up if needed?

- Do you own or rent your equipment?

Lesson 3: Response Time = Cost Savings

Our 60-minute response vs 3-day wait for insurance panel:

- Less water migration

- Less secondary damage

- Lower final costs

- Faster return to operations

Every hour of delay = more damage = higher cost

Lesson 4: Business Continuity Should Be Priority

Ask potential vendors:

- Have you done commercial properties our size?

- Can you work after-hours if needed?

- How do you minimize business disruption?

- What’s your largest commercial job completed?

Red flags:

- “We treat it the same as residential.”

- “You’ll need to close during restoration.”

- “Business continuity isn’t our focus.”

Lesson 5: Documentation Protects You

Our scientific documentation meant:

- No insurance disputes

- No questions about necessity of work

- No claim denials

- Complete transparency

Demand from your restoration vendor:

- Daily moisture logs

- Thermal imaging documentation

- Photo documentation throughout

- Final verification reports

Lesson 6: Priceless Assets Need Specialized Care

Cricket Australia had World Cup trophy and Don Bradman memorabilia. You might have:

- Expensive equipment

- Critical servers/data

- Irreplaceable documents

- High-value inventory

Ensure your restoration vendor:

- Understands the stakes

- Has experience with high-value properties

- Can provide references

- Has appropriate insurance coverage

Lesson 7: Cheap = Expensive

The lowest quote will cost you more in:

- Extended timeline (lost revenue)

- Inadequate equipment (poor results)

- Potential mould (secondary claims)

- Business disruption (immeasurable)

According to Master Builders Australia, inadequate initial response to commercial water damage is a leading cause of prolonged business interruption and inflated final costs.

The $2.50 Washer That Cost Thousands

Here’s the irony of both Cricket Australia floods:

First occasion: $2.50 washer failed. Three floors flooded.

Second occasion: Another failure. Two floors flooded.

A $2.50 part caused tens of thousands in water damage restoration costs.

Prevention lesson: Regular maintenance of hot water systems, plumbing fixtures, and appliances.

Annual plumbing inspection cost: $200-$500

Cost of not doing it: $15,000-$30,000+ in emergency restoration

For commercial property managers: Factor preventive maintenance into operating budgets. It’s not an expense—it’s insurance.

Why Cricket Australia Called Us Again (And What It Means for You)

After the 2020 restoration, Cricket Australia had a choice for future needs:

They could call anyone. Shop around. Get competitive quotes.

They call us.

Why?

Not because we’re cheapest. We’re not.

Because we deliver results:

- Fast response (60 minutes, even public holidays)

- Professional equipment (can handle any scale)

- Scientific process (documentation, monitoring, verification)

- Zero mould (5,000+ properties, never had mould issue)

- Business continuity (understand commercial needs)

- Trust (protected priceless memorabilia twice)

This is the standard your commercial property deserves.

Is Your Commercial Property Prepared?

After reading this case study, ask yourself:

Do you know who to call if water damage happens tomorrow?

Do you know if they can handle a 350m² emergency?

Do you know if they have the equipment capacity needed?

Do you know their response time on weekends and public holidays?

If you answered “no” to any of these, you’re not prepared.

Commercial Water Damage? We’ve Got You Covered

Emergency commercial restoration: 1300 682 563

✓ Restored Cricket Australia HQ (twice)

✓ 100+ staff accountants practice (Easter weekend)

✓ Hospitals, medical centers, offices

✓ 350m² capable (or larger)

✓ Business continuity focused

✓ 60-minute response 24/7

✓ $200,000+ equipment fleet

✓ Complete insurance documentation

✓ Serving Metro Melbourne & Mornington Peninsula

Request emergency planning consultation:

Even if you don’t have water damage now, we can help you prepare:

- Emergency response plan development

- Vendor evaluation

- Equipment capacity assessment

- Business continuity planning

- Prevention recommendations

Call 1300 682 563 for consultation.

Or learn more:

- Commercial Water Damage Services

- Our Professional Equipment

- Emergency Water Extraction

- What Does Water Damage Cost?

The Cricket Australia Standard

Late afternoon. Public holiday. 350m² flooded. World Cup trophy at risk.

15 days later: Complete restoration. Zero damage. Business operating.

From 7 dehumidifiers to 12. From 13 air movers to 30. From 70% humidity to safe levels.

This is commercial water damage restoration done right.

Does your commercial property have an emergency plan?

About The Squeaky Clean Team

Since 2007, we’ve specialized in commercial water damage restoration across Melbourne. From small offices to 350m² headquarters, we’ve got the equipment, experience, and expertise to handle any commercial property emergency. IICRC certified. Trusted by Cricket Australia, major accounting firms, medical facilities, and hospitality venues.

When Australia’s cricket heritage was at risk, they called us. Twice.

Emergency number: 1300 682 563

Email: sales@squeakycleanteam.com.au

Address: 219/87 High St, Prahran VIC 3181